Our strengths

-

12+

years of experience

in the industry -

25+

engineers in the team

-

100+

projects completed

-

1M+

devices manufactured

How do we work to achieve

your goals effectively?

-

Problem

At the beginning, together with the Customer, we define the problem, the possible ways of solving it and its risks; we then prepare a schedule and estimate the cost. An appropriate work methodology is important; as far as we are concerned, this involves ‘design thinking’, so-called which recognises the possible range of the Customer's needs and allows an appropriate solution to be proposed, but one which, possibly, was not what we originally intended.

-

High-Tech Solution

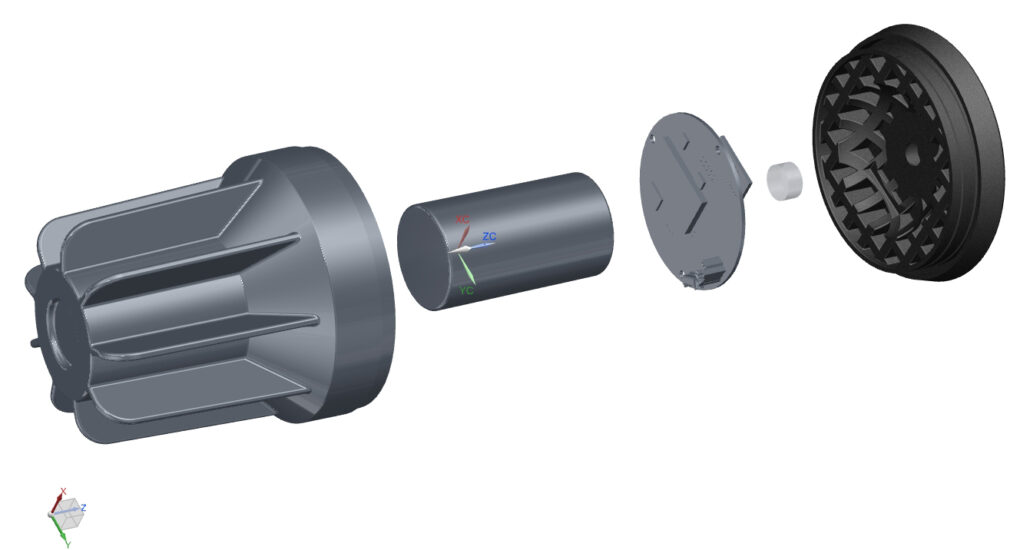

In the next stage, we try to transform the idea into hardware and software architecture with specific technical parameters. On this basis, a workshop for technological solutions is selected, a precise work plan is built and internal executive documentation is created, setting out the engineers' future work.

-

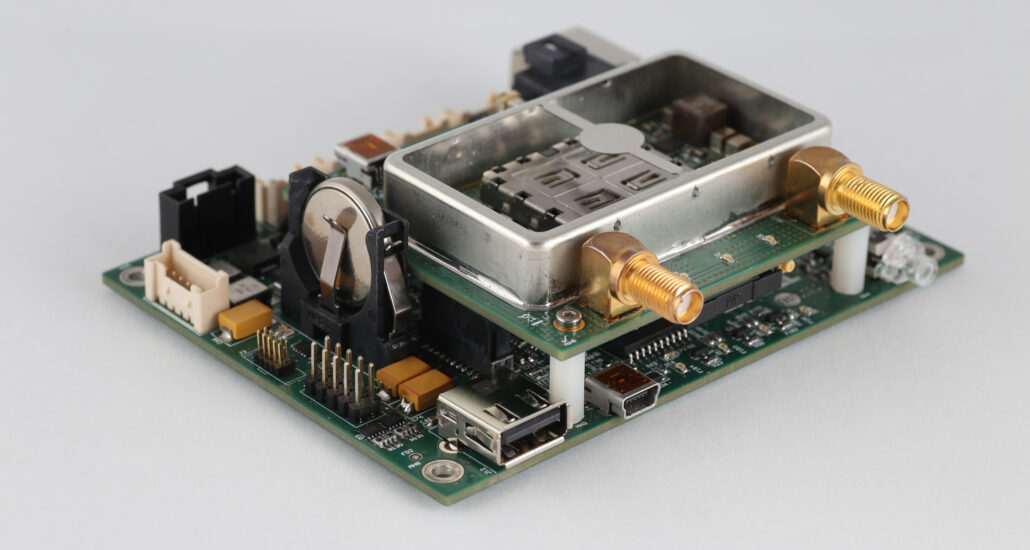

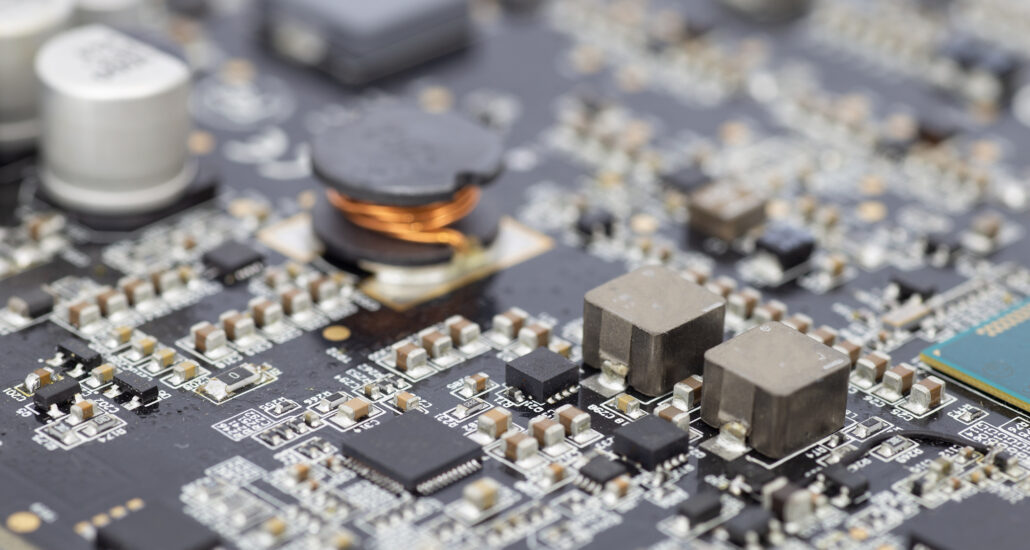

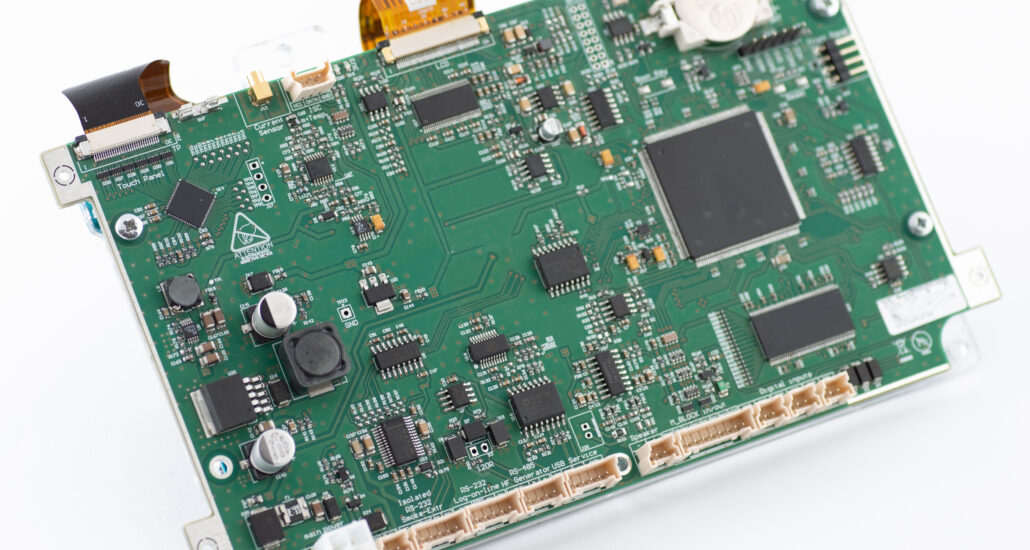

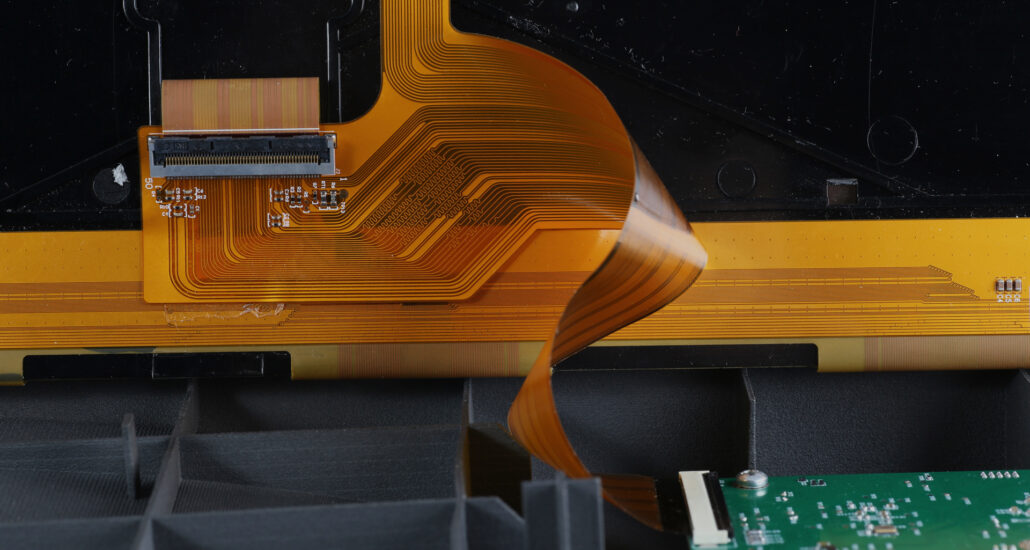

Designing an electronic device

In most cases, the design of an electronic device is a fundamental component of the work to achieve the project's goals. At this stage, our engineers design and prototype a dedicated electronic solution, based on the agreed specification and list of requirements. Depending on the complexity of the project, several conceptual verification procedures are carried out, the Proof-of-Concept so-called.

-

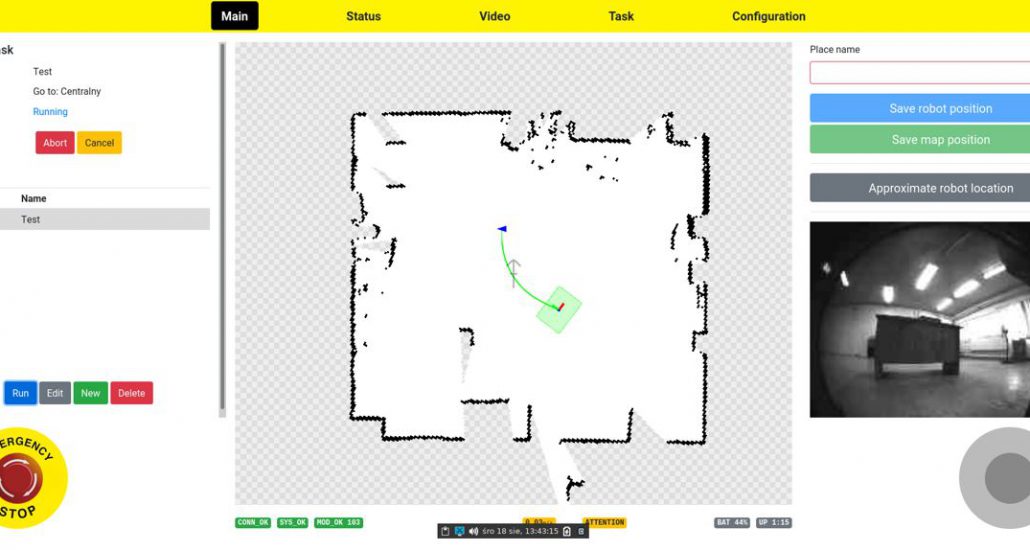

Software

Developing and implementing cornerstone software, is the next stage in the development of an electronic device. Initially, our engineers install the system software into the development platform and then into the target hardware. Depending on the complexity of the project, the test strategy is designed and implemented separately.

-

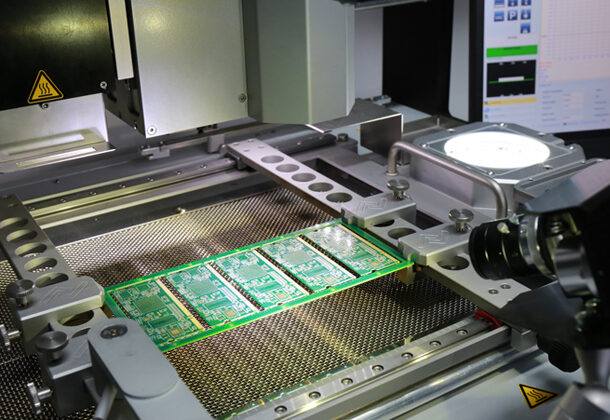

Prototype

Before implementation takes place, we conduct a trial production series, or ‘pilot’, so-called. The purpose of this stage is to identify problems affecting production of the device, itself and the production testing process. This is the area of ‘Design for Test’ (DFT) and ‘Design for Manufacturability’ (DFM) activities. It is also the right moment to introduce any other design adjustments and improvements, generally understood as ‘Design for Excellence’, so-called (DFX).

-

Production supervision

This is the stage for starting production, monitoring the supply chain and reacting to changes that may occur in it. Particular attention is paid to the availability and lifetime of the components of the device. Although this is essentially the area of competence of an EMS provider, we help in maintaining continuity of production, in terms of product maintenance and development and we also monitor production yield, especially in the first production batches.

-

Our services

Our team uses its extensive experience to implement even the most complex of electronic systems. We can offer comprehensive support for the entire project or just for selected tasks, in an indicated phase. See the structure of our services.

Offer -

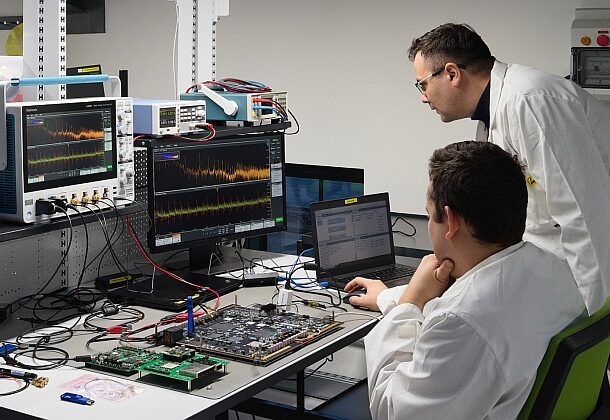

Why us?

We support the implementation of projects at every stage when creating a new product, from development research, through prototyping, to mass production, inclusively. Our team’s expertise includes both electronic systems, based on modern, high-speed digital circuits FPGA, DSP and SoC, as well as analogue solutions, from dedicated signal

Why us?