What form does the process take?

OBJECTIVE: obtaining a prototype (demonstrator) and going through the test phases in the operational environment to develop the final form of the technology + achieving TRL VIII or IX

-

Tests

In addition to functional testing, we develop a test strategy by also introducing reliability, acceptance and pre-certification tests. Systematisation of tests, in both hardware and software, enables the eighth level of technological readiness (TRL VIII) to be achieved.

-

Updates

We make changes and improvements to hardware and software based on information obtained from testing. We further optimise the project by taking into account production requirements, both in terms of yield, as well as cost, speed of assembly and post-production tests. This is the area of DFX - Design for Excellence: (DFT - Design for Test, DFM-Design for Manufacturing, DFA - Design for Assembly).

-

Certification

We are preparing the ‘gold-sample’ so-called, which is tested for compliance with the relevant regulations in an accredited laboratory. Depending on the situation, our engineers take part, directly or indirectly, in these types of tests.

-

Pilot project

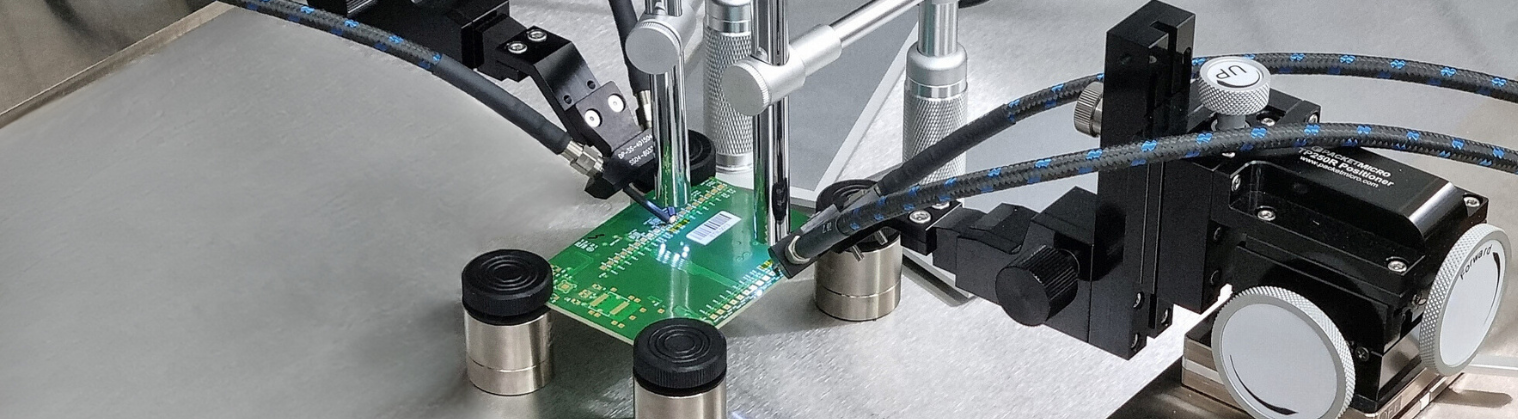

We design and make production testing tools, in order to complete the production of a pilot series.

What can we do for you?

We can develop a hardware and software test plan

We can analyse and make improvements related to Design for Excellence (DFM, DFT, DFA)

We can develop production testing protocols

We can implement engineering compliance tests (pre-compliance)

We can support the certification process

We can support the process of obtaining patent protection

We can execute and supervise the pilot series

Implementation details

The transition from the prototype phase to the finished product is one of the most difficult challenges in the process of manufacturing electronic devices. That which gets results is experience, which allows the device itself to be appropriately prepared as also the tests for the subsequent production process. Analyses and improvements in the scope of the Design for Excellence, so-called, include improvement of the production, testing and assembly process, aimed at the efficient and smooth delivery of the product to the market. Recently, there is also talk of a new type of improvement to electronic design: “Design for Change”, i.e. enabling the production of an electronic circuit with the use of substitutes, without the costly process of having to redesign the printed circuit. Although such possibilities are quite limited, FastLogic engineers are involved in product improvements in all of the above-mentioned areas, both in projects implemented from the beginning and those that have migrated to us.

The product preparation stage is also a series of tasks related to mechanics, as well confirmation of a product’s compliance with the relevant standards. Our engineers take part in these and other tasks related, for example, to the preparation of substantive parts of patent applications, wherever possible. The culmination of the work is the implementation of a pilot project, i.e. a series of device trials.

Structure and details of our services

-

Research and Analysis

Each project includes a technological analysis. Usually, this is an introduction to the project, but is often a recurring element in the development process and consists, not only of conceptual sub-projects (PoC), for the initial, practical qualification of a given solution, but also all kinds of audits, measurements, simulations and tests.

Read more

-

Project

The main design work includes the development of hardware and software architecture, as well as diagrams, libraries, PCB printing mosaics and, of course, the software of a given hardware platform. In addition, are those activities related to compliance with relevant standards, improvements on price, for example and various tests and documentation.

Read more

-

Production

We strive to maintain a high production yield and respond to the potential instability of product supply, in the face of changing market conditions. We provide continuous engineering support and monitor the production process.

Read more