Our Lab

-

50GHz

TD band

-

6GHz

RF + EMI band

-

40GHz

VNA band

-

25Gbps

Max. interface speed

-

5

Measuring stations

-

15kVA

Max. power at the work station

-

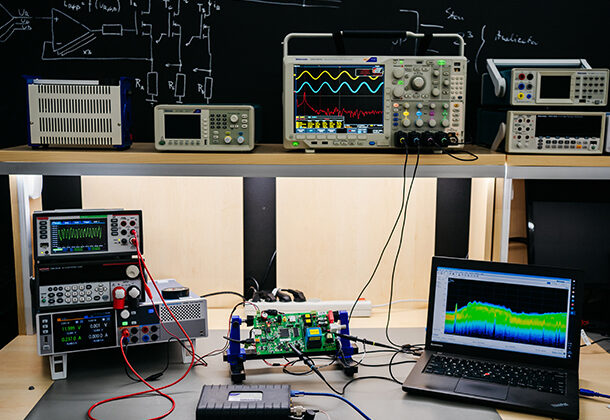

Time domain measurements

Measurements of various electrical waveforms, up to 50GHz (3.5 GHz, in situ) for general diagnostics and qualification of electronic circuits. Current measurements with precision multi-meters and current probe in the band, up to 120MHz. High voltage, multi-channel measurements with differential probes (up to 1.2 KV) and standard probes (up to 2.5 KV).

-

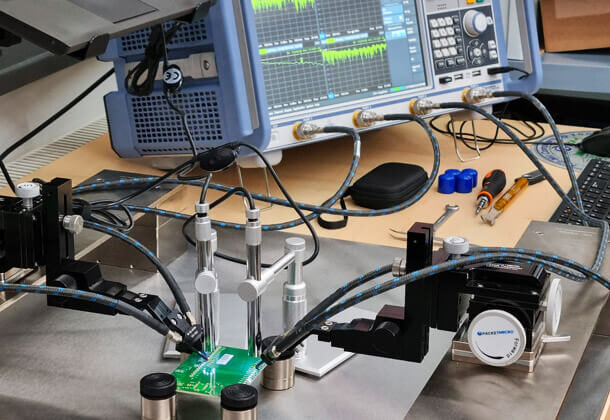

Frequency domain measurements

Characterisation of RF lines (e.g. PCB micro-strip lines, connectors, cabling, etc.) using VNA in the band up to 40GHz, e.g. for budgeting multi-gigabit connection losses and the extraction of quadruple simulation models.

Measurements with a spectrum analyser (up to 6 GHz) for synchronicity with the time domain (up to 3 GHz) for the purposes of the diagnostics of transmitting and receiving systems (RF) and EM compatibility (EMI). We measure conducted disturbances (artificial network) and radiated disturbances from both near and afar.

-

Power measurements

Using a specialised power analyser and a set of probes and tools, we perform a measurement analysis of power consumption and generation for the needs of diagnostics and characterisation:

- BMS systems and chargers;

- DC and AC converters in the power range from uW to kW;

- Ultra-low power consumption (short- and long-term profiling);

- PLC (Power Line-Communication) communication systems;

- EH (Energy-Harvesting) systems

The maximum power available in the laboratory is 15kVa.

-

Compatibility tests

Depending on the project’s needs, we rent specialised equipment and conduct compliance measurements, such as:

- IEEE802.3 (np. 100Gb CAUI4, KR4/CR4)

- JEDEC DDR3/DDR4

- PCIe Gen. 1/2/3

- other.

Our Workshop

-

3 days

average time to assemble the prototype

-

4

assembly stations

-

0.4mm

minimum BGA raster

-

0201

the smallest mounted element

-

1

ESD zone

-

> 100 000

components in stock

-

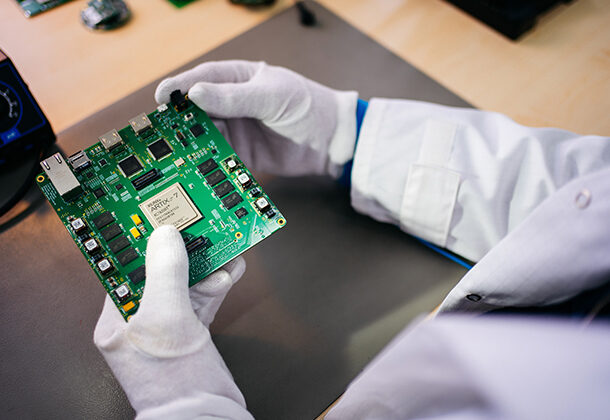

Own workshop facilities

In order to reduce the costs of prototyping, we, at FastLogic, run and develop our own workshop facilities. We have a comprehensive warehouse of components (currently over 114,042 components, over 1,600 types) and high-quality soldering tools, chemicals and other materials, necessary for assembly work. The work is carried out in a separate zone at positions with appropriate ESD protections in accordance with the standard

PN-EN 61340-5-1: 2009. We can boast a very high quality of prototyping, not different from the precision of automatic assembly. As a result, the first prototypes can be tested for the Customer, meeting high technical and visual requirements. -

Semi-automatic assembly of BGA systems

For particularly technologically advanced projects, FastLogic uses the professional BGA-Rework ERSA HR600/2 machine that enables the semi-automatic assembly of BGA systems with high process repeatability, thanks to the use of vision positioning systems for components. The undoubted advantages of this machine include the double temperature control of the soldering process, which makes the assembly of even the most complex BGA elements safe and secure for the systems themselves.

IT facilities

-

3

Servers

-

60

physical processors for logical

-

768GB RAM

for logical synthesis and numerical analyses

-

Data and licences

Due to the confidential nature of the research and development work commissioned, FastLogic has its own local IT facilities, which are used to store critical data. The infrastructure, in this area, includes 2 Dell R610 class units that store distributed project repositories and CI/CD virtual machines. Depending on need, our engineers also use the above resources to work with the dedicated tool software necessary, for the proper implementation of projects.

FastLogic licenses three leading CAD/EDA tools: Altium Designer, Cadence OrCAD, Mentor PADS.

-

Calculations

For the most advanced electronic projects at FastLogic, we have invested in a dedicated computing unit, which is used, for example, to simulate wave phenomena in the problems of signal integrity and power integrity and an extensive synthesis of logic circuits. This allowed the overall level of research and development work to be raised when designing electronics containing high-speed (>10Gbps) digital interfaces (for example Intel Atom processors, FPGA circuits).

The high professionalism of research and development, in the field of electronics, enables our engineers to approach the most serious challenges in the telecommunications market and in hardware data processing.

Our certificates

- ISO 9001:2015 — View certificate — The quality management system at the FastLogic meets the requirements of ISO 9001:2015 for: scientific and laboratory research, development, design and production in electronics and software development.

- ISO 27001:2023 — View certificate — The information security management system at the FastLogic meets the requirements of ISO 27001:2023 for: scientific and laboratory research, development, design and productionin electronicsand software development.

- AQAP 2110:2016 — View certificate — The quality management system at FastLogic meets the requirements of AQAP 2110:2016 in the field of: scientific and laboratory research, development work, design, and production in the field of military electronics and software.

- ISO 14001:2015 — View certificate — The PN-EN ISO 14001 standard contains requirements for an environmental management system, the fulfillment of which can help organizations achieve environmental and economic goals. The basic task of the standard is to support environmental protection and prevent pollution.